TOC

SPONSORED BY NANOZEN

What More Can We Do to Protect Our Workers from Silica Exposure?

Workplace Noise Measurement Can Be Easier

BY WINNIE CHU

In 2018, a $400 million settlement was reached between six global mining companies and South African miners who suffered deadly health issues from inhaling silica and other harmful airborne particulates on the job. Mining processes, as well as many other industrial operations, generate hazardous aerosols that potentially contain lead, silica, coal, arsenic, alumina, and asbestos fibers. Such operations require ongoing air sampling for exposure and health and safety compliance purposes.

Standard occupational particulate sampling involves drawing a known volume of air from the worker’s breathing zone and collecting the aerosol sample onto a filter. Filters are then sent away to an accredited lab to identify and quantify hazardous materials. It can take weeks to obtain the filter analysis data, which seriously impedes timely interventions to pinpoint and correct problems. Without timely interventions, an entirely preventable class of occupational diseases that may include silicosis and chronic obstructive pulmonary disease (COPD) continues to threaten workers’ health.

Validating Controls

In January 2022, the International Council on Mining and Metals (ICMM) published a position paper (PDF) on considerations for the adoption of real-time particulate monitoring (RTPM). According to the paper, global mining companies Teck, BHP, Vale, Alcoa, and Freeport-McMoRan have all taken the initiative and used considerable internal resources to investigate and study the use of real-time particulate monitoring in real-world settings. Anglo American, though not included in the position paper’s reported case studies, indicated through personal communication to me that it is also investigating RTPM.

Teck’s study focused on building a business case for implementing real-time monitors to mitigate respiratory disease, which is the major cause of premature death for miners. BHP investigated a scalable solution for minimizing respiratory risks by combining RTPM data with geolocation, as well as integrating sensors into Industrial Internet of Things (IIoT) frameworks. Vale evaluated RTPM instruments as tools to reduce silica exposure, and Alcoa focused on RTPM’s usefulness for validating critical control effectiveness and monitoring protocols. Freeport-McMoRan evaluated both real-time particulate instruments and same-shift silica analysis tools.

ICMM and the mining companies recognized the value of real-time particulate monitors as an integral part of critical control management, especially for identifying unexpected or uncontrolled hazardous situations. Real-time particulate monitors—specifically, optical particle counters, or OPCs, calibrated with the aerosol of interest—are necessary to verify that critical controls are performing effectively at all times. The mining company group set out eight guiding principles for effective monitor use, including preparing for field work, selecting the most appropriate instrument, validating control effectiveness, conducting field sampling, communicating findings effectively, and communicating with stakeholders.

For example, in 2020, Teck Resources in Canada issued a press release that describes how crystalline silica dust can enter a worker’s breathing zone during mining operations. Teck took advantage of real-time dust monitoring technology to gain detailed, rapid data on dust exposure levels. “This advancement in real-time particulate monitoring represents a fundamental shift for the industry and helps us improve on our commitment to protecting the long-term health of Teck employees,” said Lawrence Watkins, Teck Resources’ vice president of health and safety.

ICMM has issued several calls to action to manufacturers of real-time monitors, including enabling compositional identification of particulates such as silica. Among inhalation hazards, respirable crystalline silica (RCS) has received much attention for its comparability to asbestos fibers. While it will take time for manufacturers to productize real-time monitors capable of compositional identification, the United Kingdom’s Health and Safety Executive (HSE) has developed a direct-on-filter method—MDHS101/2, Crystalline Silica in Respirable Airborne Dust: Direct-on-Filter Analyses by Infrared Spectroscopy or X-ray (PDF)—to determine RCS concentration. Utilizing portable Fourier Transform Infrared Spectrometry (FTIR), this method can now be conducted on site, immediately post-shift, without having to send filters out for lab analysis. Some of the mining companies’ reported case studies include the use of the portable FTIR method. (A similar method is also available from the International Organization for Standardization: ISO 16258-1:2015, Workplace Air—Analysis of Respirable Crystalline Silica by X-ray Diffraction—Part 1: Direct-on-Filter Method.)

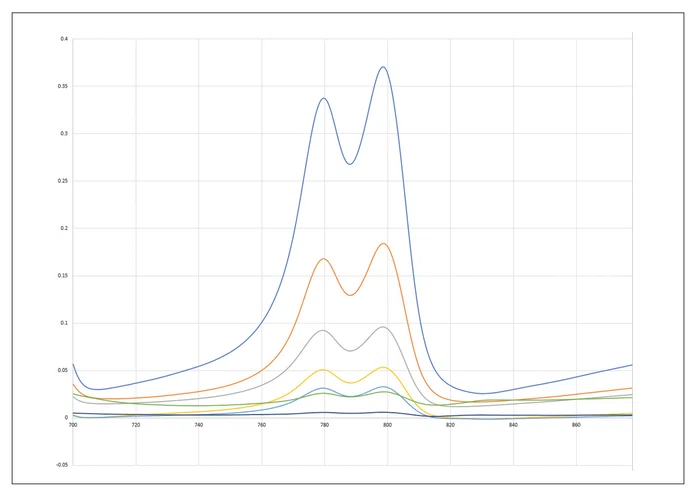

Whereas HSE developed the FTIR method for 25 mm filters, NIOSH’s Field Analysis of Silica Tool (FAST) was developed for 37 mm filters. This analysis method takes advantage of the specific silicon-oxygen doublet peak in the infrared spectroscopy (see Figure 1) to identify and quantify silica collected on a PVC filter. The original study, published in the Journal of Occupational and Environmental Hygiene in October 2018, compares seventy-five dust samples from both metal and nonmetal mines with FAST FTIR as well as the regulatory-approved traditional laboratory X-ray diffraction analysis (XRD). NIOSH concluded that mine-specific calibration factors can improve the level of agreement between RCS concentrations determined via a field-based FTIR method as compared to XRD analysis in the laboratory.

Figure 1. FTIR calibration spectra of silica with doublet peak around 800 cm-1. (Click or tap on the figure to open a larger version in your browser.)

To determine silica on a filter, FTIR on-filter analysis requires placing the filter or filter cassette directly in a portable FTIR instrument in the field. This FTIR instrument will require the creation of calibration curves for RCS (or other aerosol chemicals such as nickel oxide and nickel sulfide) that have been validated once using traditional laboratory analytical instruments. For example, silica can be analyzed by either laboratory X-ray diffraction or inductively coupled plasma mass spectrometry (ICP-MS). Since the infrared spectroscopy method is non-destructive, filters can still be sent away for analysis either as validation or quality control, if required. Many other industries besides mining companies are using this on-site direct-on-filter method to obtain crucial exposure and control data immediately post-shift. These filters can then be shipped away to the lab; besides XRD or ICP-MS, they can perhaps be analyzed by liquid chromatography mass spectrometer (LC/MS) instruments for organics.

Effective Protection

Effective and timely quantitation of respirable crystalline silica is crucial to reduce the risk of developing RCS-related lung disease and cancer. The direct-on-filter analysis method has proven to be a very powerful tool for timely identification of sources and problem areas. Hygienists increasingly employ this cost-saving methodology on site. The percentage of RCS over a full shift can be determined as soon as it ends. Dangerous conditions can be discovered immediately, and corrective actions taken to implement controls and protect workers more effectively.

The case studies initiated by ICMM and a group of major mining companies confirm the urgent need for additional IH tools besides the pump/filter and current analysis methods to improve protection of workers from harmful airborne exposures. The mining companies’ initiatives determined that real-time particulate monitors were able to provide early detection of equipment performance degradation and timely exposure warnings. Combining real-time data with geolocation allows the source of particulates to be pinpointed and controlled much faster than was previously possible, greatly improving prevention of overall aerosol exposures in a workplace.

WINNIE CHU, MSc, PhD, is an expert in nanosensor technology and a former faculty member at the University of British Columbia. She founded Nanozen in 2007. She currently serves on the environmental sensor review panel at the U.S. National Science Foundation.

Send feedback to The Synergist.

Resources

Health and Safety Executive: Method MDHS101/2, Crystalline Silica in Respirable Airborne Dust: Direct-on-Filter Analyses by Infrared Spectroscopy or X-ray (PDF).

International Council on Mining and Metals: “Considerations for the Adoption of Real-Time Particulate Monitoring” (PDF, January 2022).

Journal of Occupational and Environmental Hygiene: “A Comparison of Respirable Crystalline Silica Concentration Measurements Using a Direct-on-Filter Fourier Transform Infrared (FT-IF) Transmission Method vs. a Traditional Laboratory X-ray Diffraction Method” (October 2018).

NIOSH: “Mining Product: FAST—Field Analysis of Silica Tool” (September 2018).

Teck: “Real-Time Air Quality Monitoring Technology Helps Inform Decisions to Reduce Dust Exposure Inside Haul Truck Cabs” (March 2020).