Thinking Outside

the Confined Space Box

Application of Prevention through Design Principles to Confined Spaces

BY NANCY PEARCE

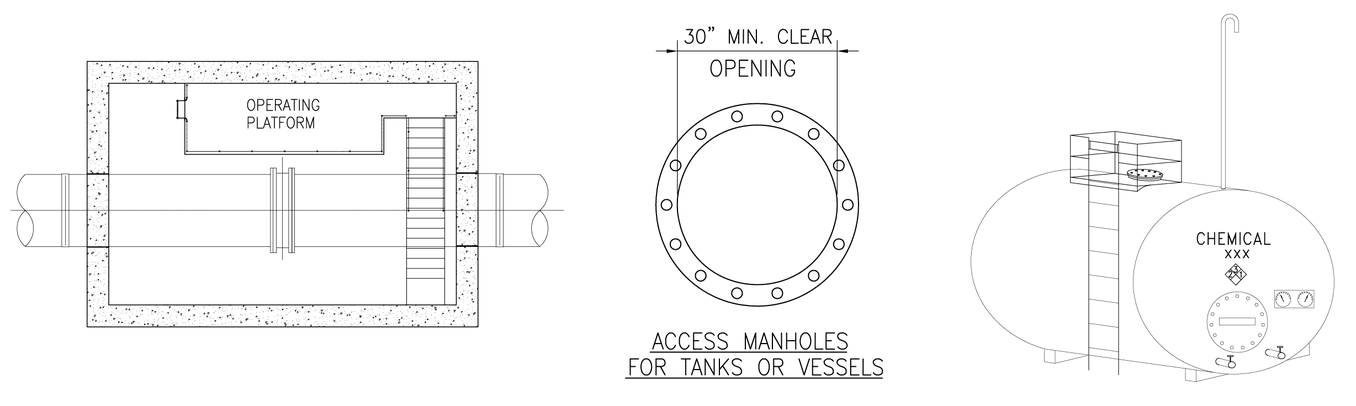

The drawings above are from the San Francisco Public Utilities Commission’s Safe Design Guidelines. For more information, see the sidebar.

Fatalities in confined spaces remain a concern despite regulations and efforts to communicate with workers and employers about these hazards. In the United States, the Bureau of Labor Statistics (BLS) Census of Fatal Occupational Injuries indicates that an average of 92 confined space fatalities occurred each year from 1997 through 2011. In 2011 alone there were 7 fatalities in confined spaces in California, prompting the state to launch a confined space entry emphasis program the next year.

By definition, confined spaces are not designed for human occupancy. Yet it is often necessary to enter these spaces for maintenance, inspection, cleaning, or repair. With thoughtful planning, many of these confined spaces—and the need to enter them—could be eliminated entirely. If it isn’t possible to eliminate a confined space completely, good design can minimize the hazards within the spaces and allow for the safe, non-entry rescue of workers. These same design principles can often be applied to existing confined spaces where redesign can eliminate or minimize hazards. Still, up-front safe design is generally recognized to be more cost effective than a retrofit at preventing injuries and fatalities in confined spaces.

NIOSH has long recognized that one of the best ways to prevent and control occupational injuries and illnesses and fatalities is to minimize or eliminate hazards in the design phase. In 2007 the agency launched its Prevention through Design (PtD) initiative, which sits at the pinnacle of the hierarchy of controls.

“PtD is the most effective means of preventing worker injury, illness, and death,” says NIOSH PtD Coordinator Jonathan A. Bach, PE, CSP, CIH. “The NIOSH PtD initiative ultimately seeks a culture change, where designing-out worker hazards at the planning stage becomes the expected norm. In boardrooms and design review rooms, we want to hear, ‘Why, of course we try to keep worker hazards out of our designs and plans.’”

PtD is facilitated when owners and operators responsible for confined space safety provide sufficient resources for safe design and assign safety professionals and engineers to collaborate during the early stages of a capital project. For a PtD process to function effectively, confined space owners and operators must understand the hierarchy of controls and recognize which confined space hazards and risks can be reduced through improved design or redesign.

To learn about recent accomplishments and current work in prevention through design at NIOSH, see the new PtD “

Program Performance One-Pager

” (PPOP).GUIDANCE AND STANDARDS

Among the existing guidance applicable to PtD and confined spaces is ANSI/ASSE Z590.3-2011 (R2016) Prevention through Design Guidelines for Addressing Occupational Hazards and Risks in Design and Redesign Processes

. Although not specific to confined spaces, this standard addresses PtD concepts and provides guidance on including PtD within an occupational safety and health management system. AIHA’s Confined Spaces Committee released a fact sheet in 2014 that provides examples of ways to design or redesign confined spaces. A PDF of this document is available from the AIHA website

.

Increasingly, safe-design concepts, some of which affect confined space safety, are being incorporated into new standards. For example, the American Society of Agricultural and Biological Engineers (ASABE) S607 standard is intended to reduce risk from asphyxiation, poisoning, and explosions when entering manure storages by specifying ventilation requirements and parameters. Another ASABE standard, EP470, sets forth existing practices on manure storages that help minimize the hazards of manure gases to livestock and humans, and limit the potential for drownings at manure storage sites. In addition, organizations such as the San Francisco Public Utilities Commission have developed guidelines for internal use that include PtD concepts (see the sidebar below). The newly released NFPA 350

Guide for Safe Confined Space Entry and Work

includes a chapter specifically on PtD for confined spaces and will serve as a “repository” for references to confined space design and redesign documents. (For more information about NFPA 350, see “Above and Beyond the Minimums

” in the October 2015 Synergist.)

Don’t look at your confined spaces the way you have in the past—that is, don’t simply issue permits without considering other options.

PTD EXAMPLES IN CONFINED SPACES

When designing or redesigning a confined space, several options are available for eliminating or minimizing hazards. These include changes that eliminate the need for entry, eliminate the confined space itself, and allow workers to be safely rescued in the event of an emergency.

Eliminate the Need for Entry

Many confined space entries could be eliminated by modifying equipment and its installation. For example, critical valves can be located outside the confined space.

Eliminate the Confined Space

A key method to eliminate a confined space is to eliminate one or more of the OSHA criteria for defining a confined space. If a space is not a confined space, then it cannot be considered a permit-required confined space. OSHA defines a confined space in general industry as one that meets all of the following criteria:- is large enough to enter and perform work

- has limited or restricted means of entry or exit

- is not designed for continuous human occupancy

If we eliminate any one of these three criteria, we have eliminated the confined space. (The new OSHA standard on confined spaces in construction, which was finalized in May 2015, uses similar criteria.)

Criteria 1: the space is large enough to enter and perform work

. The easiest way to eliminate a confined space is to design the space so that it is too small for anyone to physically enter. Inability to enter due to size keeps employees out of harm’s way and eliminates coverage under OSHA’s confined spaces standard. Spaces that already exist but do not need to be entered can be redesigned by welding permanent plates or grates in place or otherwise modifying the space to make it too small to enter. I once inspected a laundry facility that had a vertical pipe chase in the corner. Employees entered the space periodically to retrieve socks or other items that had fallen into it. A simple solution was to block off the space or minimize the need to enter it by placing a screen or fine grating over the opening. If access to the space would be required in the future—for example, to repair a broken pipe—a temporary locked cover could be installed. Criteria 2: the space has limited or restricted means of entry or exit.

The installation of a standard staircase rather than a spiral staircase or ladder reduces the likelihood that a space would be considered to have a limited or restricted means of entry or exit. Spaces can be designed so that workers don’t have to contort their body to enter or exit, and by providing entry and exit locations at regular intervals, the design of a space can ensure that employees’ ability to exit is not restricted by distance. Designing spaces above ground for housing equipment with a standard doorway access is another way to eliminate a confined space.Criteria 3: the space is not designed for continuous human occupancy during normal use.

Some spaces can be designed for regular occupancy by installing ventilation and lighting. Mechanical equipment should be properly guarded and electrical equipment installed just as it would be for normally occupied spaces.

Eliminate Serious Hazards

PtD can be used by owners and operators, as well as contractors and subcontractors, to design or redesign the confined space so that it no longer has serious hazards. Examples include:- Substitute or eliminate hazardous chemicals that present potential hazardous atmospheres. Combustible liquids with higher flash points can be used, as can chemicals that are less toxic or corrosive.

- Eliminate serious safety hazards by installing fixed guards or covers on mechanical and electrical equipment hazards; railings or fall protection points into the space; and energy isolation lockout points outside of the space. Removing or guarding against exposure to sharp, heated, or slippery surfaces is another way to protect workers from serious hazards.

- Prevent engulfment or entrapment hazards. Design pipes, valves, and line breaks to allow for blocking and bleeding of lines outside of the space; design the space opening to allow for easy emptying of contents; and alter configuration of the space to prevent entrapment.

IF ALL ELSE FAILS, DESIGN FOR RESCUE

Owners and operators of confined spaces, as well as contractors and subcontractors, can use PtD to facilitate rescue in confined spaces. Here are just a few examples:

- allow for two openings for rescue

- allow unobstructed access of rescue and retrieval equipment

- permanently mount a davit arm, a receiver, or other fixed anchor point at the space opening

But perhaps the most effective way to protect workers from the hazards of confined spaces is to change the mindsets of OHS professionals. Don’t look at your confined spaces the way you have in the past—that is, don’t simply issue permits without considering other options. Think outside the confined space box: consider designing new or redesigning existing confined spaces to eliminate or minimize the confined space entry risk to workers.

NANCY PEARCE, CIH,

is senior fire protection engineer at NFPA, the staff liaison for NFPA 350, and chair of AIHA’s Confined Spaces Committee. She can be reached at (617) 984-7439 or npearce@nfpa.org

.A Public Utility’s Approach to Prevention through Design for Confined Spaces

By Carolyn M. Jones and George Bibbins

The San Francisco Public Utilities Commission (SFPUC), the city’s water and wastewater utility, developed Prevention through Design guidelines in 2007 that have been integrated into the agency’s infrastructure upgrade programs. The agency’s engineering and safety groups continue to collaborate to produce and update this set of engineering drawings and associated notes, illustrating regulatory- and internal policy-based safe design requirements and best practices. Now in its second revision, the guidelines have grown to include twenty-four drawings that cover safe design relative to confined spaces, chemical storage, ergonomics, fall prevention, signage, access, ventilation, and noise.

SFPUC utility vault retrofitted with guardrail around entry hatch, per SFPUC Safe Design Guidelines.

Specific to confined spaces, the guidelines include dedicated drawings and recommendations for vaults, water storage tanks, and chemical tanks. Other guideline drawings and recommendations address confined space-related issues such as the locations of valves and equipment, ventilation, guardrails and other means of fall prevention, hatches, platforms, ladders, and stairs.

Adhering to the hierarchy of controls, the guidelines prioritize elimination of confined spaces—for example, by relocating outside of confined spaces equipment and controls normally contained inside, or by improving access with larger entryways equipped with stairs rather than ladders. The guidelines also highlight engineering and administrative controls such as built-in retrieval mounts, ventilation, lighting, and signage.

Carolyn Jones, SFPUC’s Health and Safety Manager, who leads the effort to develop and maintain the guidelines, notes that given the serious risk confined space entry poses to employees, Prevention through Design is an important strategy for increasing safety.

Please contact Carolyn Jones or George Bibbins using the information provided below for additional information or to request a copy of the guidelines. For more information about SFPUC’s activities, visit

www.sfwater.org

.

CAROLYN M. JONES, CIH,

is the SFPUC Health and Safety Program Manager. She can be reached at (415) 550-3577 or cjones@sfwater.org

.

GEORGE BIBBINS, CIH,

is an industrial hygienist with SFPUC. He can be reached at (415) 550-3573 or gbibbins@sfwater.org

.RESOURCES

AIHA: Prevention through Design: Eliminating Confined Spaces and Minimizing Hazards

(May 2014).

American National Standards Institute: ANSI/ASSE Z590.3

Standard, Prevention through Design: Guidelines for Addressing Occupational Risks in Design and Redesign Processes

(September 2011).

National Fire Protection Association: NFPA 350,

Guide for Safe Confined Space Entry and Work

(2016).

NIOSH:

Prevention through Design

.The Synergist

: “Above and Beyond the Minimums: An Overview of NFPA’s New Guide for Safe Confined Space Entry and Work

”(October 2015).

thesynergist | TOC | NEWSWATCH | DEPARTMENTS | COMMUNITY