Asbestos

in Focus

An Introduction to Laboratory Analysis and Quality Assurance

BY ED RUTKOWSKI

According to the latest data from the United States Geological Survey, domestic consumption of asbestos in the U.S. has fallen from a peak of more than 800,000 metric tons in 1973 to a little more than 350 metric tons in 2015. But the long latency of asbestos-related diseases ensures that the health consequences of asbestos will be with us for years to come. And despite the well-known risks of exposure, some 2 million metric tons of asbestos were produced worldwide in 2015.

The once-ubiquitous use of asbestos in products ranging from insulation and roofing materials to coatings and plastics, combined with continuing production in countries such as Russia and Brazil, ensure that sampling for asbestos will long remain relevant for industrial hygienists. In the U.S., renovation of older buildings containing asbestos and the thicket of regulations governing such projects will continue to require knowledgeable professionals for sampling and abatement. And for some of the laboratories that serve IHs, analyzing those samples remains a source of steady business.

WHO'S COUNTING

While many IHs are likely familiar with the sampling procedures for asbestos, they might not know what happens to those samples at the lab, and how labs arrive at the results they report to IHs. Most analysis of asbestos air samples follows NIOSH method 7400, which is a fiber-counting method. (NIOSH is currently revising the method; see the sidebar below for more information.) Microscopists prepare samples by opening up the cassette, cutting out a portion of the filter, and mounting it on a slide, typically through use of acetone vapor and triacetin resin. The method calls for phase-contrast microscopy (PCM), a technique that renders visible the changes in light waves as they pass through objects, at a magnification of 400x.

Because PCM can’t distinguish between asbestos fibers and non-asbestos fibers, and because exposure to other elongate mineral particles (EMPs) has been associated with adverse health effects, the method instructs microscopists to count all fibers in a field that have certain dimensions. The fibers must be at least three times as long as they are wide, with a minimum length of 5 µm (microscope calibration using the HSE/NPL test slide determines the minimum detectable fiber diameter of 0.25 µm). To identify fibers in the appropriate size range, microscopists use the Walton-Beckett graticule, which has gradations to assist with accurate sizing.

The counting rules for the 7400 method might strike an uninformed observer as surprisingly complex. Microscopists are instructed to count fibers that cross once through the boundary of the circular field, but not fibers that cross twice—in other words, if you can’t see at least one end of a fiber, you shouldn’t count it. Asbestos fibers often occur in bundles of fibrils; if the fibrils seem to be part of the same bundle, the whole bundle counts as one fiber. According to the method, microscopists must count at least 20 fields. They are to stop counting when they reach 100 fibers, or when they’ve counted 100 total fields—whichever comes first. The average number of fibers per graticule field is used to determine the number of fibers on the filter.

Depending on the quality of the sample and the loading of fibers on the filter, the 7400 method can require a lot more time than the typically low cost of PCM analysis might suggest.

“People probably think it doesn’t take very much time,” says Derek Popp, the head of quality control at the Wisconsin Occupational Health Laboratory in Madison. “But if the filter’s not heavily loaded, you’re counting 100 fields, and it just takes a lot of time to go through it.”

Popp knows about asbestos analysis from firsthand experience. He spent four years as an analyst in the late 1980s, when asbestos was front and center in the public consciousness. Congress had passed the Asbestos Hazard Emergency Response Act (AHERA) in 1986, which established inspection and abatement standards for asbestos in school buildings and led to a surge of asbestos-related work. (AHERA required a different method for counting fibers in air samples: transmission electron microscopy, or TEM.) At the time, Popp estimates that his lab was taking in approximately 50 bulk and air samples a day.

“It gets pretty tedious when you’re spending eight, nine hours on and off a microscope,” he says.

While the amount of asbestos work at Popp’s lab has tailed off since then, he still sees asbestos samples, usually following demolition projects.

Asbestos analysis still accounts for steady business at EMSL Analytical, Inc., according to Scott VanEtten, CIH, EMSL’s national director of industrial hygiene. EMSL currently has a number of analysts listed on AIHA’s Asbestos Analyst Registry (AAR), a program that establishes standards for quality control related to the practices prescribed by the 7400 method.

VanEtten is well aware of the challenges of fiber counting. “It takes a special person to do microscopy work,” he says.

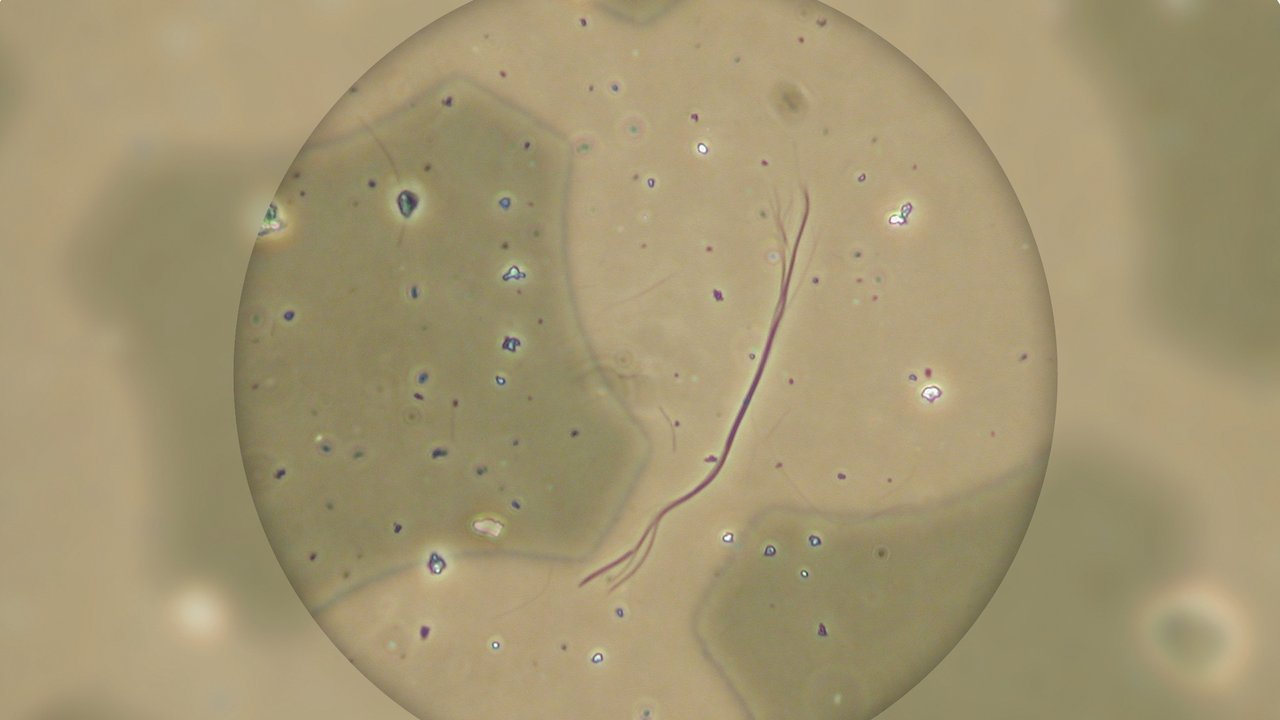

IMAGE: Phase contrast micrograph showing a chrysotile fiber crossing the boundary of a circular viewing field, photographed originally at 400x. Reproduced from “The Quality of Fiber Counts Using Improved Slides with Relocatable Fields” by Thomas W. S. Pang and Martin Harper, Journal of Environmental Monitoring, vol. 10, pages 89–95 (2008). Used with permission from the Royal Society of Chemistry.

NIOSH Is Revising Method 7400

The most commonly used method for PCM analysis of asbestos is getting a makeover. According to NIOSH’s Martin Harper, who is drafting the revised method, one of the most important changes to method 7400 will address quality assurance.

The revised method will introduce a verification procedure involving reference slides with relocatable fields. These slides will allow other analysts to “look at exactly the same area [of a slide] as another microscopist,” Harper says. Slides with relocatable fields have been commercialized by Thomas Pang of Ryerson University in Toronto, but can also be made by the laboratory. Harper and Pang have published papers in the Journal of Environmental Monitoring that describe the results of round-robin testing with such slides. The papers suggest that the slides can help improve the precision of analysts’ counts.

Other changes to the method will include a new procedure for mounting sample material on slides. In addition to the mounting procedure in the current method, which involves acetone and triacetin resin, labs will have the option of using a dimethylformamide solution and a synthetic resin called Euparal. As described in a paper that appeared in the July 2011 issue of the Annals of Occupational Hygiene, Euparal produces a long-lasting mount that allows long-term archiving of slides.

“We’re not requesting that all laboratories change from acetone/triacetin to dimethylformamide Euparal,” Harper says of the new procedure. “We’re offering it as an alternative.”

Once the revised method is reviewed internally at NIOSH, it will be made available for public review and comment. The agency does not have a timetable for completing the revision.

A MATTER OF TIME

One variable for microscopy work is the quality of the microscopist’s eyesight, which can degrade over time. In addition, research suggests that some types of asbestos are easier to see under a microscope than others. Amphibole fibers are straighter and longer than chrysotile fibers, which have a serpentine shape. “Most microscopists can see and count the amphibole asbestos quite well under the phase contrast microscope,” says Martin Harper, chief of the NIOSH Exposure Assessment Branch of the agency’s Health Effects Laboratory Division in Morgantown, W. Va. “But they can have problems with chrysotile, especially when the fibers are very thin.”

Still, Harper says that other factors are more important for analysts’ performance than strength of eyesight.

“The biggest single factor, in my opinion, in how well an analyst can locate chrysotile fibers under PCM is not actually the setup of the microscope, provided the microscope is set up according to the method,” Harper says. “Nor do I really believe that it’s the visual acuity of the microscopist. I think the most important factor is the length of time that the microscopist spends looking for chrysotile fibers and racking the focus of the microscope up and down to ensure that they visualize several different planes.”

In papers published by the Journal of Environmental Monitoring, Harper and his coauthors discussed the results of a study in which microscopists analyzed special reference slides with relocatable fields developed by Thomas Pang of Ryerson University in Toronto. The results indicate that the new slides can be an effective training aid for analysts.

“Giving them a slide where you can tell them what they’re going to see in some of the fields and then asking them to look and examine,” Harper says, will encourage analysts to take more time, “and they’re probably going to have a much better result.” The forthcoming revision of NIOSH 7400 will recommend the use of relocatable reference slides, which are already incorporated as a recommendation in ISO Method 8672.

QUALITY ASSURANCE

NIOSH 7400 requires all microscopists to begin the day by examining an in-house reference slide (one of a number of field samples with a range of loadings that laboratories keep specifically for this purpose). The counts from that slide must fall within established limits before the microscopist can proceed to analyze field samples. In addition, OSHA requires all labs to participate in a round-robin testing program with at least two other labs using field samples.

The AIHA Proficiency Analytical Testing (PAT) Programs are one means of independently verifying laboratories’ ability to provide quality data. These programs measure proficiency using laboratory-generated samples. There are two separate AIHA PAT programs related to asbestos. Laboratories that wish to demonstrate proficiency in analysis of air samples as described by the NIOSH 7400 method participate in IHPAT, the Industrial Hygiene Proficiency Analytical Testing program. To demonstrate proficiency in analysis of bulk samples, labs participate in BAPAT, the Bulk Asbestos Proficiency Analytical Testing program. As of late June, 760 laboratory locations were participating in IHPAT and 261 in BAPAT.

The IHPAT program distributes filters with variable loadings of chrysotile, amosite, or man-made mineral fibers to participating laboratories and compares the labs’ results to the mean of selected reference laboratories to ensure that the labs’ analysis is statistically sound. Testing for IHPAT is held quarterly. The PAT Board reviews the overall performance results to ensure that there are no anomalies.

The BAPAT program sends bulk building material samples to participating labs. The labs are required to classify the materials as asbestos-containing or not, and to identify the asbestos type (or types) present in the samples. In addition, participants are asked to provide semi-quantitative estimates of the amount of asbestos present, and identification and semi-quantitation of other fibrous and nonfibrous components of the samples, where possible. Evaluation of the laboratory’s performance is based on sample classification, asbestos identification, and semiquantitation of the asbestos types.

Individuals who wish to demonstrate competency in PCM analysis can participate in the AAR and its related proficiency testing program, the AAT. The AAR and AAT were originally intended for analysts who perform PCM analysis at a job site—for example, to determine whether asbestos is present during a demolition project. Today, many analysts who work in laboratories also participate in AAR and AAT.

AIHA Laboratory Accreditation Programs, LLC (AIHA-LAP) accredits labs for many types of analyses under IHLAP, the Industrial Hygiene Laboratory Accreditation Program. Currently, 119 laboratory locations in the U.S., Canada, and elsewhere are accredited for asbestos PCM. IHLAP-accredited laboratories undergo site assessments every two years where an AIHA-LAP site assessor fully examines the lab’s quality management system and technical competency to ensure compliance with ISO/IEC 17025:2005 and other AIHA-LAP requirements. They also very closely look at proficiency testing results while on site.

Popp and VanEtten are well acquainted with all of these programs. Both are serving their second term on the PAT Board. The Wisconsin Occupational Health Laboratory, where Popp works, is accredited for both IHLAP and BAPAT, as are many of EMSL’s laboratories. And both are adamant that IHs should have more confidence in the data from accredited labs vs. non-accredited labs.

“That’s because there’s somebody coming in there and actually watching what the [microscopist] is doing,” Popp says. “AIHA-LAP goes through 7400 basically line by line to make sure that you’re doing everything that’s in the method. They’re guaranteed to spend half a day on air asbestos and half a day on bulk asbestos. It could go over into a second day.”

ADVICE FOR PRACTITIONERS

Asked to identify common mistakes IHs make when collecting asbestos samples for laboratory analysis, Popp immediately mentions filter overload. “If you put a pump on somebody for eight hours, go by and check it to see what the loading is,” Popp suggests. “If they’re accumulating a lot of dust on the filter, chances are it won’t be able to be counted.”

Other analytical methods for analysis of asbestos air samples include NIOSH 7402 for TEM. Unlike PCM, which is non-specific for fiber counting, TEM can distinguish between asbestos and non-asbestos fibers. However, it is much more costly and time consuming.

Methods for analysis of bulk samples include NIOSH 9200 and EPA/600/R-93/116, both of which utilize polarized light microscopy (PLM). IHs who sample bulk material might have trouble determining how many samples to send for analysis. VanEtten and Popp agree that IHs generally take too few samples. A single sample from, say, 2,000 pounds of material decreases the likelihood that analysts will find any asbestos to report, even if asbestos is present at the site.

But what might be most helpful for IHs and laboratories alike is establishing a clear line of communication. Understanding the challenges analysts face when determining the asbestos content of a sample can help IHs accurately communicate the results to their clients.

“I think it’s really useful for any industrial hygienist to maintain a dialogue with the laboratory and to learn as much as possible about the method,” Harper says, “because that gives them a much better understanding of the variance within the method and what that means in interpreting the final result.”

ED RUTKOWSKI is editor in chief of The Synergist. He can be reached at (703) 846-0734 or erutkowski@aiha.org.

Author's note: The individuals interviewed in this article—Martin Harper, Derek Popp, and Scott VanEtten—are members of AIHA's Sampling and Laboratory Analysis Committee (SLAC). The SLAC provides a forum for exchanging ideas and information about sampling and analysis of chemicals as they impact the workplace and the community and to participate in the development and analysis of related technological and regulatory issues. Members interested in joining the committee are encouraged to contact SLAC Chair Ryan LeBouf at ryanlebouf@yahoo.com.

RESOURCES

AIHA Laboratory Accreditation Programs, LLC: LAP Policies and Guidelines.

AIHA Proficiency Analytical Testing Programs, LLC: AIHA PAT Programs Participation Policies (PDF, September 2012).

Annals of Occupational Hygiene: “Comparison of Mounting Methods for the Evaluation of Fibers by Phase Contrast Microscopy” (July 2011).

ISO 8672: Air Quality—Determination of the number concentration of airborne inorganic fibres by phase contrast optical microscopy—Membrane filter method.

Journal of Environmental Monitoring: “The Quality of Fiber Counts Using Improved Slides with Relocatable Fields” (October 2008).

Journal of Environmental Monitoring: “Continued Participation in an Asbestos Fiber-counting Proficiency Test with Relocatable Grid Slides” (November 2009).

NIOSH: Current Intelligence Bulletin 62: Asbestos Fibers and Other Elongate Mineral Particles: State of the Science and Roadmap for Research (April 2011).

NIOSH: Method 7400, Asbestos and Other Fibers by PCM (PDF).

U.S. Geological Survey: Asbestos: Mineral Commodity Summaries (January 2016).

For more information about asbestos proficiency testing and laboratory accreditation, visit www.aihapat.org, www.aihaaccreditedlabs.org, and www.aiha.org/registries.

thesynergist | TOC | NEWSWATCH | DEPARTMENTS | COMMUNITY

AIHA's Director of Government Affairs, Aaron Trippler, reported in October that OSHA is working on an updated compliance directive for workplace violence. The updated directive is expected to be released in February 2016.

Public support for legalizing marijuana has reached an all-time high in Gallup Polling with 58 percent of Americans supporting the movement. Last January, Fox News reported the stock price for a medical marijuana machine company increased 57 percent after Colorado legalized recreational use. The state reported over $5 million in taxed and regulated sales of marijuana during the first week of legalization and more than $200 million during the first four months.

- Eric Nelson and Jeremy Slagley

The first definitions for respiratory protection terms appeared in a letter to the editor published in the December 1982 issue of the AIHA Journal. Alan Hack, Chuck Fairchild, and Barbara J. Skaggs of the Los Alamos National Laboratory Industrial Hygiene Group proposed definitions for four terms: Fit Factor, Protection Factor, Field Performance Factor, and Worker Use Factor. The letter noted that published industrial hygiene studies referred to "several different measurements of respirator efficiency or performance, with 'Protection Factor' being used to refer to each of them." A response from NIOSH staff in the March 1983 AIHAJ introduced additional terms, including Assigned Protection Factor.

For an explanation of the HSE/NPL test slide, see the article "The Phase Shift Test Slide Interpretation" (PDF) by OSHA's Daniel Crane and NIOSH's Martin Harper.