The NIOSH Decision Logic for OEBs

Applying Occupational Exposure Bands

NIOSH Occupational Exposure Banding Team

The following individuals helped develop the NIOSH decision logic for OEBs:

• Stephen Gilbert, MS

• George Holdsworth, PhD

• T.J. Lentz, PhD

• Andy Maier, PhD, CIH, DABT

• Lauralynn Taylor McKernan, ScD, CIH

• Melissa Seaton, MS

• Christine Whittaker, PhD

• Charles Barton, PhD

• Christine Uebel, BS

BY LAURALYNN TAYLOR MCKERNAN, MELISSA SEATON, AND STEPHEN GILBERT

Occupational hygienists often face the challenge of protecting worker health from chemicals that don’t have occupational exposure limits (OELs). Despite the absence of OELs, risk management decisions need to be made and applied. To address the critical need for risk-based exposure guidance for the many thousands of unregulated chemicals in commerce, NIOSH has developed a draft occupational exposure banding methodology that can be used across various industries. No tool solves every situation, but occupational exposure banding can help in certain situations where some data exists on a chemical, yet no OEL is assigned. Occupational exposure banding facilitates a rapid evaluation of health risk and quickly identifies chemicals to be evaluated for elimination or substitution.

TERMINOLOGY

In October 2014, OSHA published a notice in the Federal Register seeking comment on chemical management and permissible exposure limits (PELs) as well as other strategies that could be implemented to address workplace conditions where workers are exposed to chemicals without OELs. The notice mentioned several alternate OEL approaches, including occupational exposure banding.

Occupational exposure banding is a mechanism for quickly and accurately assigning chemicals into categories (“bands”) on the basis of potency and health outcomes associated with exposure to chemicals. The output of this process is an occupational exposure band (OEB). Several similar terms are in use, including hazard banding, health hazard banding, exposure banding, and occupational exposure banding. In Europe, hazard banding is more common because it is used with control banding systems such as Stoffenmanager and the Advanced Reach Tool (ART).

NIOSH uses the term occupational exposure banding because the methodology derives an OEB based upon health outcomes and potency. Stakeholders can apply an OEB to identify an appropriate control strategy and to make risk management decisions. Some stakeholders may use OEBs in concert with control banding, but others will not. Regardless of the terminology, the methodology has real promise as a new tool in our toolbox.

NIOSH OEB PROCESS

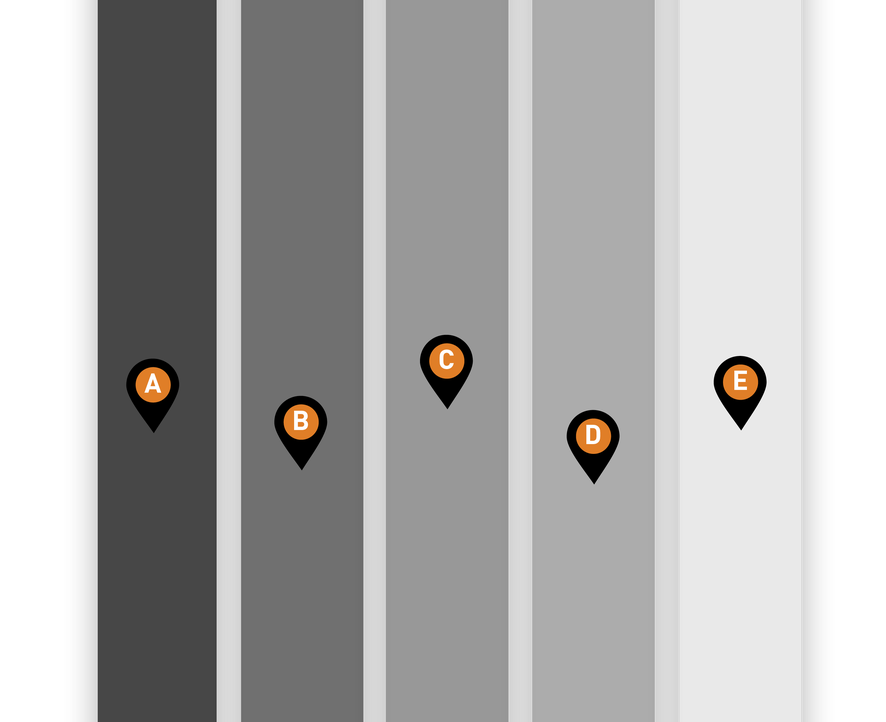

The draft NIOSH banding methodology is based on a five-band system, ranging from Band A to Band E. Each OEB corresponds to a range of exposures that is likely to protect the health of exposed workers. Band E is the most protective band, while Band A is the least protective.

A chemical is assigned to a band on the basis of both the potency of the chemical and the severity of the health outcome. Band A and Band B are designed to include chemicals that produce reversible health effects or chemicals that produce adverse effects at relatively high concentration levels. Chemicals that cause serious or irreversible effects and chemicals that elicit adverse health effects at low concentration ranges are categorized into Band C, Band D, or Band E.

A novel attribute of the NIOSH methodology is that it applies a three-tiered approach to occupational exposure banding (Figure 1). Each tier of the process has different requirements for data sufficiency, which allows a variety of stakeholders to use the methodology in many different situations. The most appropriate tier for banding depends on the availability and quality of the data, how it will be used, and the training and expertise of the user. While Tier 1 requires relatively little information and modest specialized training, each successive tier necessitates more chemical-specific data to successfully assign an OEB. A primary goal of Tier 1 is to give the user a quick summary of the most important health effects associated with exposure to the chemical of interest, and to quickly identify extremely toxic chemicals that should be considered for substitution or elimination. Tier 2 requires the user to examine a number of publicly available databases and extract relevant toxicological and weight-of-evidence data to be used in the NIOSH banding algorithm. Tier 3 employs expert judgment to critically evaluate experimental data and discern toxicological outcomes.

Figure 1. Overview of NIOSH OEB process.

The NIOSH Tier 1 occupational exposure banding methodology is based on and aligned with the Globally Harmonized System of Classification and Labelling of Chemicals (GHS). The user collects GHS hazard codes and categories from NIOSH-recommended sources, and then determines the corresponding band for each of the hazard codes and categories using the NIOSH criteria. The most protective of these individual bands is selected as the OEB for the chemical. Users can likely complete this process in a matter of minutes and can use it to quickly identify highly toxic chemicals for which further banding should be considered. Figure 2 presents an overview of the steps in the Tier 1 process.

Tier 2 requires the user to search recommended databases for information related to eight standard health endpoints. Next, the user compares the extracted data, which can be either quantitative or qualitative in nature, to the NIOSH Tier 2 criteria. On the basis of NIOSH criteria, the user assigns the chemical to a band for each endpoint for which data exists. As with Tier 1, the most protective of those bands is assigned as the OEB for the chemical (provided the data surpasses minimum requirements). This process is more time-intensive than Tier 1 but produces a band with more confidence. See Figure 3 for an overview of the steps in the Tier 2 process.

NIOSH developed Tier 3 in recognition of the fact that not all chemicals can be banded in Tier 1 or Tier 2 because of potential lack of data availability in prescribed secondary data sources. Therefore, Tier 3 requires a detailed survey of the relevant primary literature and an analysis of resulting experimental data. The Tier 3 process relies on expert judgement and a critical evaluation of the available dose-response data.

Figure 3. The Tier 2 process requires users to search databases for information related to standard health endpoints.

Figure 2. The Tier 1 process involves collecting GHS hazard codes and categories.

CONFIRMATION EXERCISES AND LESSONS LEARNED

Over the last 18 months, NIOSH has shared its draft document and methodology with approximately 40 early users to assist in refinement activities. These users have participated in a four-hour prototype online training class and completed “homework” exercises. The results from this collaborative effort have allowed NIOSH to determine if users consistently and accurately achieve the same OEB as NIOSH experts.

NIOSH has also previewed the Tier 1 methodology at six AIHA local section meetings and other large stakeholder meetings, reaching at least 800 participants. These interactive sessions presented detailed examples of banding. Participants completed the Tier 1 process on their own and asked substantive questions. As a result, the Tier 1 methodology and materials have been clarified in the draft NIOSH guidance document.

In addition to various user tests, NIOSH has conducted four rounds of confirmation exercises. Part of the confirmation process has been to compare both Tier 1 and Tier 2 results from the NIOSH banding process with existing OELs. For chemicals with multiple OELs, the lowest published OEL was used. Although banding is not recommended when an OEL exists, this comparison process provided critical information. When confirming the Tier 2 process, users banded 53 chemicals that had existing OELs. In this exercise, almost all chemicals had a Tier 2 OEB at least as protective as the band containing the OEL. This exercise provided support that the Tier 2 methodology was on target.

Many lessons have been gleaned from these early interactions with users and stakeholders. Here are the top four lessons:

Users prefer short, succinct directions over detailed directions. Much like convincing users to read OEL documentation before using an OEL, convincing users to read the OEB methodology in its entirety has been difficult. When provided a comprehensive document, users tend to put it aside and consult training slides. They want to consume less information and quickly use the banding process. As a result, slide decks and pull-out informational sheets were developed for quick reference. However, not reading the details did create problems for users.

Toxicology terms don’t mean the same thing to everyone. Different users come to the table with different levels of toxicological expertise. Users of Tier 2 and Tier 3 must have a reasonably strong background in toxicology to use the NIOSH method. To address this, NIOSH is developing an online educational toxicology primer specifically for banding. The hope is that this primer will improve background knowledge.

Training is needed to conduct a Tier 2 assessment. Teaching a user how to complete a Tier 1 assessment takes little time. Significantly more time is necessary to train users effectively on Tier 2. Users of Tier 2 must be well trained in how to use the draft NIOSH method, just as training is required to select appropriate respiratory protection. NIOSH has developed a better training class with blended learning opportunities and is working on skill-check questions to aid the process.

Transcription errors happen. In many cases, if another agency has classified a chemical according to its own internal scheme as Category A, B, C, D, or E for a given endpoint, some users mistakenly put the data in the band with the same label for that endpoint on the OEB worksheets, regardless of the directions. Unfortunately, not all classification schemes agree in labeling, and banding mistakes happen as a result of this transcription error to the NIOSH process. Despite specific training on the topic, the error repeatedly happens with new users. To design-out this and other observed user errors, NIOSH has begun coding a Web-based program that will ask users to enter information directly. This program will use the information in the correct way and eliminate these common mistakes.

THE PATH FORWARD

The refining process has proved invaluable to NIOSH as we move closer to releasing a draft methodology for public comment. The interactive process has enriched the NIOSH methodology and improved its effectiveness for stakeholders. NIOSH looks forward to the next step: a public meeting where stakeholders can try out the draft methodology themselves. We anticipate that this meeting will provide significant feedback that will help us further improve the methodology. When this project is completed, stakeholders will not only have a comprehensive document describing the process, but also a methodology to apply to chemicals without OELs.

When a chemical is banded using the NIOSH decision logic, the derived OEB can be helpful in a variety of ways. But an OEB is more than just a letter or exposure concentration range. It can be used to identify potential health effects and target organs from a chemical compound. It can inform medical surveillance decisions. It can identify health risks that affect health communication messages. It can inform decisions on the implementation of control interventions. And most importantly, it can provide critical information quickly and become a valuable new tool for occupational hygiene.

LAURALYNN TAYLOR MCKERNAN, ScD, CIH, is deputy director of the Education and Information Division, CDC/NIOSH in Cincinnati, Ohio. She can be reached at lmckernan@cdc.gov or (513) 533-8542.

MELISSA SEATON, MS, is an industrial hygienist with the Education and Information Division, CDC/NIOSH in Cincinnati, Ohio. She can be reached at mseaton@cdc.gov or (513) 533-8248.

STEPHEN GILBERT, MS, is a statistician with the Education and Information Division, CDC/NIOSH in Cincinnati, Ohio. He can be reached at sgilbert@cdc.gov or (513) 533-8271.

Resources

Advanced Reach Tool.

Federal Register: Chemical Management and Permissible Exposure Limits (PELs), (October 2014).

Stoffenmanager version 6.2.1.

The Synergist: “The Banding Marches On: NIOSH Proposes a New Process for Occupational Exposure Banding” (login required; May 2014).

Tap on the graphic below to open a larger version in your browser.

thesynergist | TOC | NEWSWATCH | DEPARTMENTS | COMMUNITY