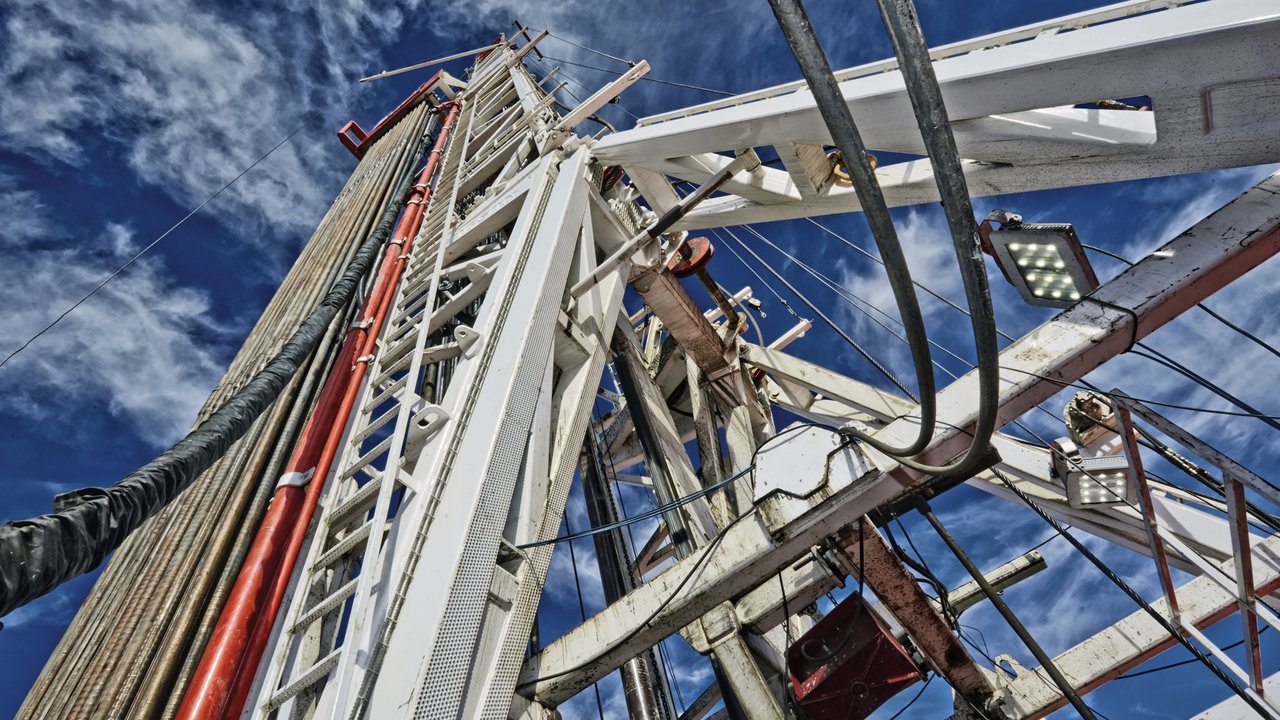

Hydraulic fracturing, a process involving high pressure, a large volume of water, sand, and a few chemicals, has been used throughout the U.S. to stimulate production from oil and gas wells since the 1940s. It is neither new nor untested. It is also not without risk, although the attention given to this process has likely focused on the wrong risks. To understand why, it’s important to begin with what this process is and is not.

CONTAMINATION INCIDENTS

Hydraulic fracturing activities comprise a short period—approximately two weeks—in the thirty-year life cycle of a typical well. The window of opportunity for mishap during well stimulation is small when compared to the duration a well may be producing. Such mishaps may result in contamination of public or private drinking water supplies. Examples of contamination events that EPA has attributed to oil and gas wells include incidents in Bainbridge Township, Ohio; in Garfield County, Colo.; in Dimock Township, Penn.; and near Killdeer, N.D.

Conclusions drawn from the Dimock study are the subject of ongoing controversy. A recent study conducted on the same wells and published in 2015 by the National Academy of Sciences (NAS) concluded that diesel-range organics found are likely the result of contamination from surface spills, not subsurface flow or infiltration during well stimulation activities. Another recent study conducted in the Wattenberg Field in Colorado published in the journal Water Research found that most methane-contaminated water wells were microbial in origin and that the remaining were the result of integrity failures such as in well casing or casing cement. It is not surprising that some of these instances occurred during the production cycle of a well as opposed to the comparatively short period one is undergoing stimulation via hydraulic fracturing.

Various regulatory entities, including EPA, have put a great deal of effort into linking the down-hole injection of water and chemicals into a well bore to drinking water contamination. In a study published earlier this year, EPA concluded that hydraulic fracturing as a well stimulation activity has not had a widespread, systemic impact on drinking water resources in the U.S. The agency found a limited number of contamination events, however. It is important to note that the study included contamination events from spills to soil migrating into surface water reservoirs. In addition, “drinking water” as defined by the study includes not only those water resources currently in use, but also those that might possibly be used in the future. EPA acknowledges that these future water resources may not be potable, nor considered drinking water by other regulatory agencies at the moment. Events meeting these qualifiers notwithstanding, the only documented events where active hydraulic fracturing activities clearly contaminated drinking water in an aquifer occurred in Bainbridge Township, Ohio, in 2007 and near Killdeer, N.D., in 2010.

Baker Hughes, a company that provides oil field services, estimates that approximately 110,000 wells were drilled domestically onshore between 2012 and 2014. Using a retroactive average figure of 36,700 wells per year for the period 2005 through 2015 yields a failure rate of approximately 1 per 184,000 wells (assuming most wells during that period were stimulated using hydraulic fracturing techniques). Is this an acceptable failure rate for progress toward domestic energy independence?

CHEMICALS USED IN HYDRAULIC FRACTURING

Much of the national “fracking” conversation has been dominated by chemicals and their possible hazards. Opponents of hydraulic fracturing and concerned citizens cite contamination events as a reason to regulate (or remove proprietary protection from) chemicals used in this process. Current peer-reviewed research—including papers published by NAS, Probate & Property, Science of the Total Environment, and the Groundwater Protection Council (GWPC)—does not appear to support a link between these events and exposure to chemicals beyond anecdotal claims. For individuals who assess exposure health risks as a vocation, the dose makes the poison—severity of response depends on dose. We recognize that some chemical substances have a dose below which little or no adverse response is observed (the LOAEL and the NOAEL). We also recognize that an exposure pathway must exist or be plausible to enable dose uptake. When subject to a minimal amount of scrutiny, dose potential for “frack chemicals” in groundwater is greatly reduced.

A product category typically used in hydraulic fracturing mixtures is a biocide. Typically, the product is injected as part of the overall chemical/water mixture for the purpose of inhibiting bacterial growth, which can lead to various equipment integrity issues. A common active ingredient in many biocides on the market today is glutaraldehyde (CAS# 111-30-8). It works well on bacteria and, in inhalation doses exceeding 0.05 ppm, can be hazardous to people, according to ACGIH. Safety data sheets indicate that glutaraldehyde typically comprises 10 to 30 percent of many overall biocide product mixtures. It may be further mixed at a rate of a half-gallon per 1,000 gallons of water in the overall “frack fluid” mixture, according to GWPC. At that rate, glutaraldehyde is present in the mixture injected downhole at a concentration of about 150 parts-per-million by volume to a depth of 3,000–12,000 feet underground depending on the shale gas formation and fractured outward from the well bore. If some of those fractures traveled thousands of feet upward through rock, the 150 ppm(v) glutaraldehyde mixture could commingle with groundwater. For an average female living in the U.S. consuming the daily amount of total water as recommended by the Institute of Medicine, the projected dose would be 5.7 mg/kg/day. For an average male, the projected dose would be nearer 6.7 mg/kg/day. EPA suggests an NOAEL for glutaraldehyde of 16 mg/kg/day. The projected dose under this hypothetical circumstance is less than half of the NOAEL for glutaraldehyde. While complete absence of this contaminant and others in drinking water stores is the target, I believe that most scientists would conclude that typical toxicants in the home pose a greater health threat. If our business is about health risks, this one is comparatively low.

References

ACGIH: Documentation of the Threshold Limit Values for Chemical Substances and Physical Agents & Biological Exposure Indices (2012).

Baker Petrolite (Baker Hughes): Alpha 1427 MSDS version 1 (PDF, 2011).

Champion Technologies: Bactron K-87 Microbiocide MSDS version 3.1 (PDF, 2010).

Colorado Oil and Gas Conservation Commission: “Summary Report of Bradenhead Testing, Gas Well Remediation, and Ground Water Investigations–San Juan Basin, LaPlata County, Colorado” (2000).

Crescent Consulting, et.al: East Mamm Creek Project Drilling and Cementing Study (2011).

Energy Institute, University of Texas at Austin: “Fact-Based Regulation for Environmental Protection in Shale Gas Development” (PDF, February 2012).

EPA: “Assessment of the Potential Impacts of Hydraulic Fracturing for Oil and Gas on Drinking Water Resources” (2015).

EPA: “Plan to Study the Potential Impacts of Hydraulic Fracturing on Drinking Water Sources” (2011).

EPA: “Reregistration Eligibility Decision for Glutaraldehyde” (2007).

EPA: “Retrospective Case Study in Killdeer, North Dakota” (2015).

EPA: “Retrospective Case Study in Northeastern Pennsylvania” (2015).

Groundwater Protection Council (GWPC): “State Oil and Gas Agency Groundwater Investigations, A Two-State Review: Ohio and Texas,” (PDF, 2011).

GWPC: FracFocus, API wells 4228931987 and 4228931944 (2012).

GWPC: Exhibit 35: Volumetric Composition of a Fracture Fluid in Modern Shale Gas Development in the United States, A Primer (PDF, 2009).

International Association for Research on Cancer: “Silica Dust, Crystalline, in the Form of Quartz or Cristobalite,” IARC Monographs 100C (PDF, 2011).

Institute of Medicine: “NIOSH Field Effort to Assess Chemical Exposures in Oil and Gas Workers” in Workshop on the Health Impact Assessment of New Energy Sources, Shale Gas Extraction (April 2012).

Institute of Medicine: “Dietary Reference Intakes: Water, Potassium, Sodium, Chloride, and Sulfate” (2004).

Science of the Total Environment: “Evaluation of Impact of Shale Gas Operations in the Barnett Shale Regions on Volatile Organic Compounds in Air and Potential Human Health Risks” (2014).

NIOSH: “Health Effects of Occupational Exposure to Crystalline Silica” (PDF, April 2002).

NIOSH Science Blog: “Preliminary Field Studies on Worker Exposures to Volatile Chemicals during Oil and Gas Extraction Flowback and Production Testing Operations” (August 2014).

Ohio Department of Natural Resources: “Expert Panel Report: Bainbridge Township Subsurface Gas Invasion” (PDF, 2009).

Probate & Property: “Regulation of Unconventional Natural Gas Development” (2011).

Proceedings of the National Academy of Sciences: “Elevated Levels of Diesel Range Organic Compounds in Groundwater Near Marcellus Gas Operations are Derived from Surface Activities” (2015).

Proceedings of the National Academy of Sciences: “Noble Gases Identify the Mechanisms of Fugitive Gas Contamination in Drinking-Water Wells Overlying the Marcellus and Barnett Shales” (2014).

Water Research: “Concurrence of Aqueous and Gas Phase Contamination of Groundwater in the Wattenburg Oil and Gas Field of Northern Colorado” (2016).

Texas Commission on Environmental Quality: “Silica, Crystalline Forms” (PDF, 2009).

The single most significant worker exposure that has been found during hydraulic fracturing activities is related to crystalline silica as alpha quartz.

Absent defects in well casing or cement, “frack chemicals” may return to the surface in a dilute mixture of liquid hydrocarbons during well flowback, the last phase of well completion prior to production. Over a period of hours or days, injected well fluids return to the surface. During this phase, the returning fluid resembles less the fluid that was injected and more the eventual production stream containing gas and liquid hydrocarbon species. The composition of this mixed stream is determined mostly by the formation that was chosen for production. Some of the hydrocarbon-based chemicals are certainly health hazards (benzene, toluene, xylenes, ethyl benzene, trimethyl benzenes, and various poly-aromatics). Information from GWPC published in Modern Shale Gas Development in the United States on the composition of hydraulic fracturing fluids suggests these species rarely, if ever, comprise a fluid mixture used to fracture a well. Some of this mixed flowback stream could contain glutaraldehyde, if used earlier in the process for well fracture. It may be in solution with various hydrocarbons that comprise the first flow of a well and typically returns at an elevated temperature (150-200°F). This mixture is caught and contained at the well site. In some cases, personnel are assigned responsibility for observing the rate at which the fluid is returning in an effort to ensure adequate storage capacity and prevent spills. Are these personnel exposed to glutaraldehyde in amounts exceeding occupational limits? NIOSH field studies published in 2012 indicate worker exposure risk for this substance is low. As explained on the NIOSH Science Blog, health hazards during this phase are more likely to result from the well production stream in the form of benzene than the mixture of water, sand, and chemicals used to stimulate the well formation.

SILICA EXPOSURES

The single most significant worker exposure that has been found during hydraulic fracturing activities is related to crystalline silica as alpha quartz (CAS# 14808-60-7), which the International Agency for Research on Cancer lists as a “known” carcinogen due to sufficient evidence linking the substance to lung cancer. Exposure by inhalation can cause cancer and silicosis, and is associated with the development of pulmonary tuberculosis, autoimmune disorders, and chronic renal disease. Exposure limits are established as a protective limit beyond which the potential risk for disease is unacceptable. Examples include the NIOSH Recommended Exposure Limit (REL) and the ACGIH Threshold Limit Value (TLV).

Sand, called proppant, is composed of crystalline silica and is used in the hydraulic fracturing fluid mixture to “prop” fractures open in the underground rock. The fractures allow gas to escape from tight shale formations. Proppant is typically chosen based on size according to American Petroleum Institute standards and mined domestically. Large variances in airborne particle size are normal and may be related to proppant size chosen for injection downhole. It is not unusual for proppant size to vary from small to large on the same well or on the same day. Other exposure variables include the amount of proppant received and transferred downhole during a shift and average worker distance from dust emission points. Occupational exposures typically occur over a 12-hour shift, which calls into question the protectiveness of limits derived for 8 or 10 hours. During periods of peak exposure, it may be possible to exceed the 30-minute excursion limit or ceiling as defined by ACGIH. Absent engineering or administrative controls or personal protective equipment, the likelihood of exceeding nearly any occupational exposure limit for silica exists when handling sand during well stimulation operations.

Why not advocate respiratory protection as a preferred exposure control for exposed workers? Ignoring the obvious response—that PPE is lowest on the hierarchy of controls—the answer is quite simple: silica exposures may exceed recognized silica exposure limits such as the NIOSH REL by a factor of 10 or more, as NIOSH has found. The upper confidence limit (at 95 percent) for many sample data sets lies well above the maximum use concentration of half-mask or filtering facepiece respirators. The shale oil and gas industry has initiated a host of engineering controls comprised mainly of dust reduction technologies aimed at reducing worker exposure.

Opponents of hydraulic fracturing in the U.S. have taken silica-containing dust as another standard to bear in the fight for community health. The extent to which respirable (PM4) silica particles can move offsite has not been well characterized as of this writing, nor have public exposure limits related to PM4 silica. The only published cancer-based health benchmark for crystalline silica in the U.S. belongs to the Texas Commission on Environmental Quality, which recommends an annual dose limit of less than 0.27 µg/m3 PM4 as silica to reduce lifetime additional cancer risk below 1 per 100,000. Although annual dose is difficult to measure, this seems a reasonable place to start. Measuring silica-containing PM4 in the public environment could be a next step in the evaluation of particulate matter beyond the well pad.

FOCUS ON WORKERS

Where are the health hazards of hydraulic fracturing? A simple evaluation of exposure pathway, magnitude potential, and severity of response points to occupational beginnings. Environmentalists and the public would do well to apply basic exposure principles and turn collective focus toward the canaries in our collective coal mine—American workers. As health scientists, we have a duty to aid their understanding of this issue and pursue measurable risk in favor of belief or suspicion.

TIMOTHY HICKS, MSPH, CSP, CIH, is the president and managing director of Hicks Health & Safety, a consulting firm located in Golden, Colo., and Charleston, S.C. He is also the chair of AIHA’s Oil and Gas Working Group. He can be reached at (888) 492-8001 or thicks@hhs-usa.com.

A Short Health Hazard Analysis of Hydraulic Fracturing

FRACKING and HEALTH RISK

BY TIMOTHY HICKS

thesynergist | TOC | NEWSWATCH | DEPARTMENTS | COMMUNITY